- Metal-based ceramic liner

- Nano ceramic product series

- Wear-resistant ceramic coating products

- Wear-resistant ceramic composite pipe components series products

- Microcrystalline high wear-resistant ceramic ball

- Special welding ceramic transfer, ceramic patch

- Ball mill metal composite ceramic liner

- PF-1016 Organic Wear-Resistant Ceramic Clay

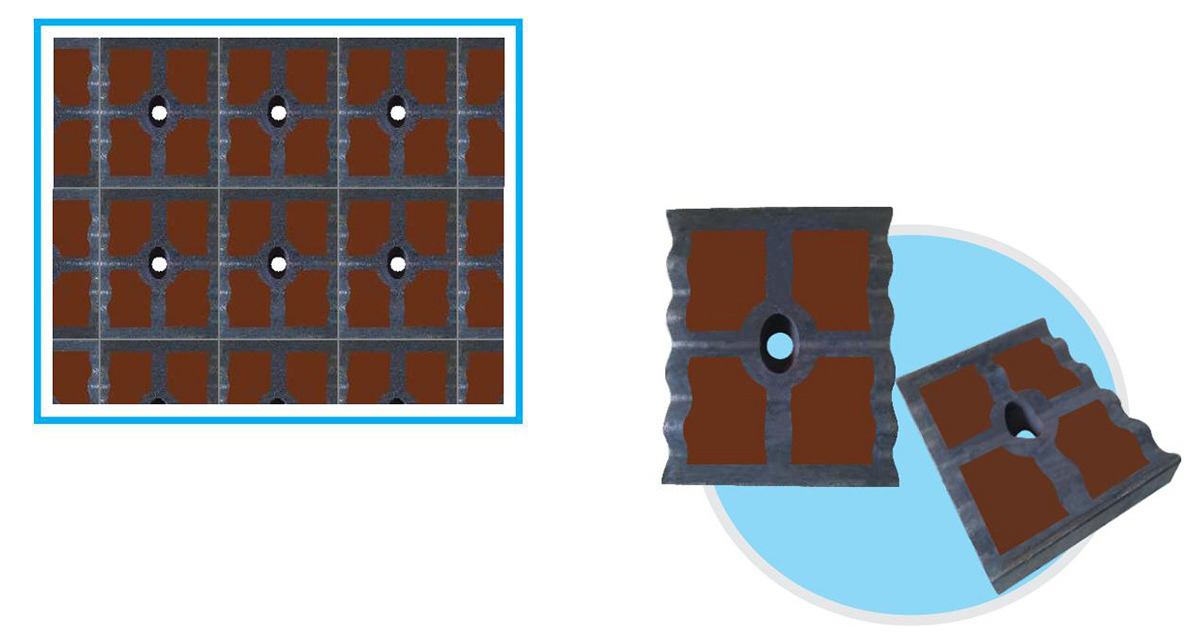

Metal Composite Ceramic Liner

The metal-ceramic composite liner for ball mill is a liner for ball mill jointly developed by the technicians of our company's provincial engineering research and development center and the School of Materials, Taiyuan University of Science and Technology. The characteristics are 40% lighter than the original ball mill high manganese steel, energy saving is about 2 kWh per ton of cement produced. Due to the use of metal composite ceramics, the wear resistance is significantly improved, and the service life can be increased by about 1-2 years. It is an alternative to high manganese steel. The new functional liner of the liner. It is an ideal product for cement enterprises to save energy and reduce consumption and improve cement quality.

Structure

The ceramic liner adopts a metal-inlaid ceramic structure, and its shape and installation method are exactly the same as the original metal liner of the mill. It has the unique characteristics of light weight, high strength, high wear resistance, no pollution, and convenient installation and disassembly. With its unique structure, the ceramic liner is especially suitable for the grinding chamber of the ball mill. Compared with the original metal liner, the installation weight is reduced by 30~42%, and the service life is about 1-2 years longer than that of the high chromium liner.

Performance index of cermet composite liner

Performance indicators of high manganese steel in the base part:

|

Grade |

tensile strength |

Elongation |

Initial hardness (Rockwell) |

Hardness after hardening (Rockwell) |

Content% |

Mn content% |

|

high manganese steel |

≥900Mpa |

≥40 |

16-19 |

≥33 |

0.9-1.12 |

11-14.0 |

Performance tips of functional part composite ceramics:

|

Grade |

AL₂0₃+ZrO+Si0₂ |

density |

Hardness (Rockwell) |

Hardness (Rockwell) |

Water absorption |

Equivalent wear |

Bending strength |

|

Composite ceramics |

≥92% |

>3.65/cm² |

9 |

80-83 |

0% |

<0.08% |

220Mpa |

Product List

Luoyang Pengfei Wear-resistant Materials Co., Ltd.

TEL:

EMAIL:lypf0379@126.com

ADD:No. 1, Pengfei Road, Industrial Cluster Area, Ruyang County, Luoyang, China

© 2021 Luoyang Pengfei Wear-resistant Materials Co., Ltd. 豫ICP备16007321号-1 www.300.cn