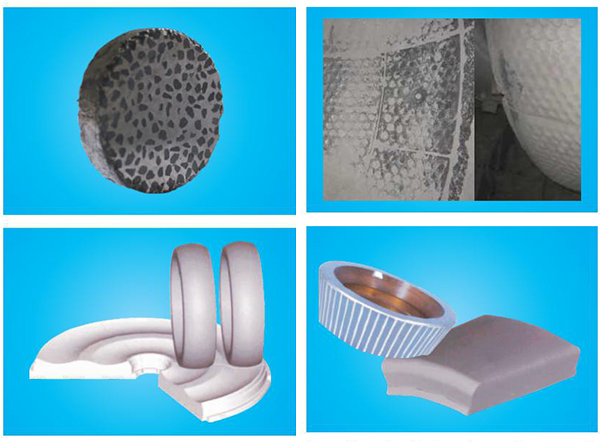

- Metal-based ceramic liner

- Nano ceramic product series

- Wear-resistant ceramic coating products

- Wear-resistant ceramic composite pipe components series products

- Microcrystalline high wear-resistant ceramic ball

- Special welding ceramic transfer, ceramic patch

- Ball mill metal composite ceramic liner

- PF-1016 Organic Wear-Resistant Ceramic Clay

Metal-based ceramic liner

Equipment wearing is severe during the crushing, processing, and transportation of materials in cement plants, power plants, and mines, especially during the crushing and processing. In order to transport large particle materials, equipment is required to feature sound wear resistance and impact resistance. Due to the high hardness, outstanding wear resistance, high fragility, lack of toughness, fragility, and weak impact resistance of wear-resistant ceramics, most wear-resistant steel plates are made of high-chromium alloy materials. Although alloy materials boast outstanding toughness, they have lower hardness and worse wear resistance compared with ceramics, resulting in the short service life of the equipment and frequent replacement of wear-resistant and vulnerable spare parts, thus causing significant economic losses to enterprises for halting the production and replacing accessories. Guided by customer needs, our company has organized engineering technicians to develop the metal-based ceramic liner in coalition with more than a dozen of professors and doctoral senior engineers from Luoyang Institute of Refractory Materials, Henan University of Science and Technology, and Zhongyuan University of Technology. As a new functional material integrating the wear resistance and metal toughness of ceramics, the metal-based ceramic liner is a qualitative leap and technological revolution in the field of wear-resistant materials.

The metal-based ceramic liners currently developed by our company are widely used in cement plants, power plants, mines, metallurgy, machinery, and other industries. With a service life more than 4 times that of wear-resistant steel plates, they not only feature excellent wear resistance, but also have excellent impact resistance. Applications include the roller skin of mine crushers, the roller sleeve, grinding disc, and liner of vertical mills, the liner of large ball mills, and equipment for crushing and conveying large particle materials. The service life is more than 4 times that of the currently used wear-resistant liner.

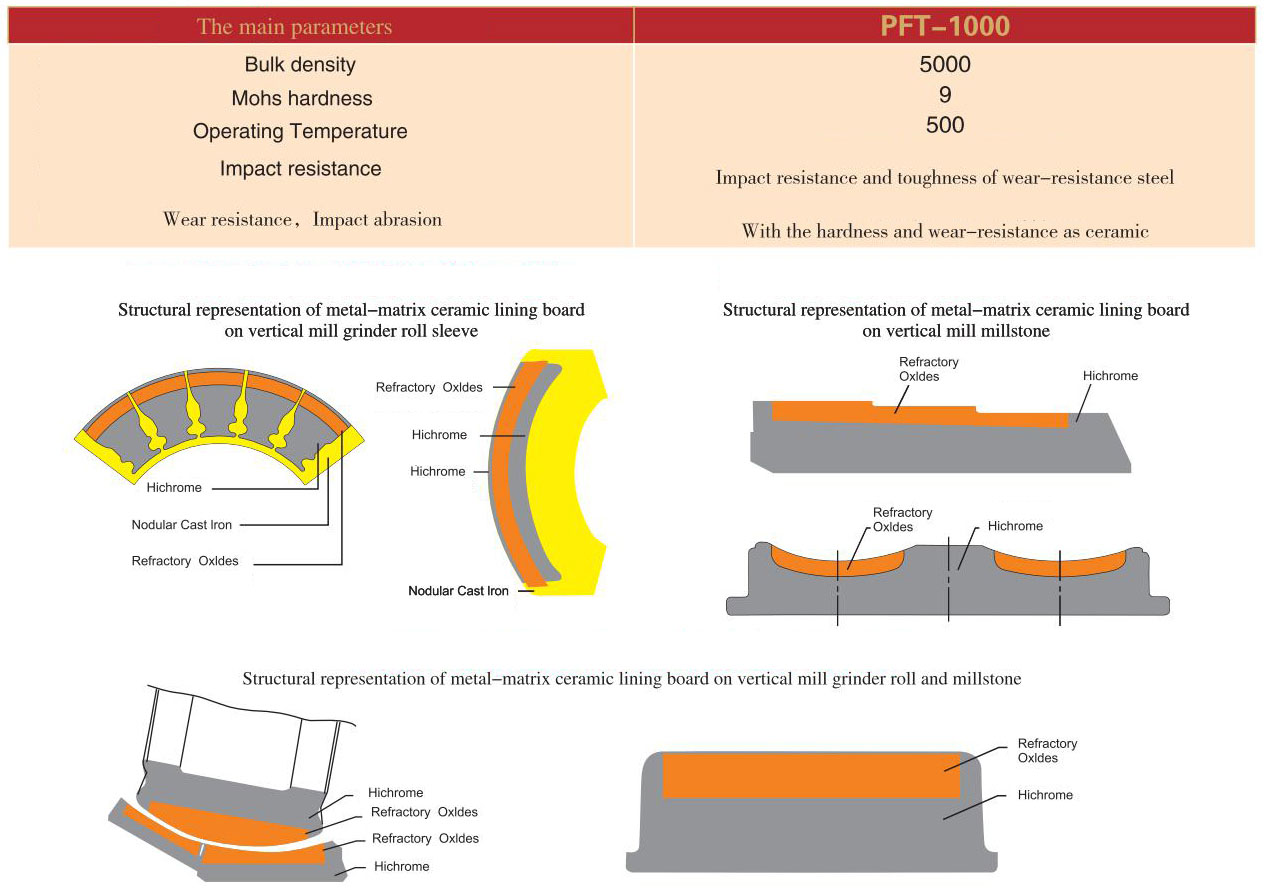

Technical properties of metal-base ceramic liners

1. Remarkable wear resistance: Since this product is a composite of ceramics and metals, it is as hard and wear-resistant as ceramic materials, and its hardness reaches grade 9 in the Moh’s Hardness Scale. The wear resistance is more than 4 times that of wear-resistant metal materials.

2. Since the metal-based ceramic liner is made of metal-based composite ceramics, it is as tough as metal and is highly impact-resistant. The toughness and impact resistance of such functional material are tens of times that of all wear-resistant ceramics.

3. Small volume density and light weight. Since the metal-based ceramic liner applies a large number of ceramic materials, its specific gravity is only 5, which is 1/4 lighter than wear-resistant steel. Also, it is easy to construct and install, easy to install, and saves labor.

4. Long service life. Since the service life of metal-based ceramic liners is more than 4 times that of wear-resistant steel, it can reduce the need for production suspension and maintenance, save investment, decrease labor intensity, and improve production efficiency.

5. It is applicable to various fields, including metallic wear-resistant materials and non-metallic wear-resistant materials. It is the only best alternative to metallic wear-resistant materials and non-metallic wear-resistant materials.

PFT-1000 Physical and chemical signs of metal-based ceramic liners

Superior properties of metal-based ceramic liners

1. Reduce maintenance costs.

5. Reduce downtime caused by online surfacing and minimize production reduction and revenue loss.

2. Do not break.

6. Low abrasion and much longer service life than surfacing welding.

3. The original shape can be maintained for a long time and the performance is stable in use.

7. Reduce operational costs.

4. Hardness is higher than surfacing, with uniform wearing and reduced power consumption.

8. The mill can be used at a higher milling pressure to improve the use and performance parameters.

There are many types of wear-resistant steel, which can be generally divided into high manganese steel, medium and low alloy wear-resistant steel, chromium molybdenum silicon manganese steel, gas corrosion resistant steel, abrasion-resistant steel, and special wear-resistant steel. Some general-purpose alloy steel is used as wear-resistant steel under specific conditions, such as stainless steel, bearing steel, alloyed tool steel, and alloyed structural steel. Due to convenient sourcing and excellent performance, they represent a large part of the source of wear-resistant steel. However, the metal-based ceramic composite material independently developed by our company will increase the service life by more than 4 times, therefore saving costs for users, improving production efficiency, and making a tremendous contribution in increasing economic benefits.

Application of metal-based ceramic liners in vertical mills

Product List

Luoyang Pengfei Wear-resistant Materials Co., Ltd.

TEL:

EMAIL:lypf0379@126.com

ADD:No. 1, Pengfei Road, Industrial Cluster Area, Ruyang County, Luoyang, China

© 2021 Luoyang Pengfei Wear-resistant Materials Co., Ltd. 豫ICP备16007321号-1 www.300.cn