- Metal-based ceramic liner

- Nano ceramic product series

- Wear-resistant ceramic coating products

- Wear-resistant ceramic composite pipe components series products

- Microcrystalline high wear-resistant ceramic ball

- Special welding ceramic transfer, ceramic patch

- Ball mill metal composite ceramic liner

- PF-1016 Organic Wear-Resistant Ceramic Clay

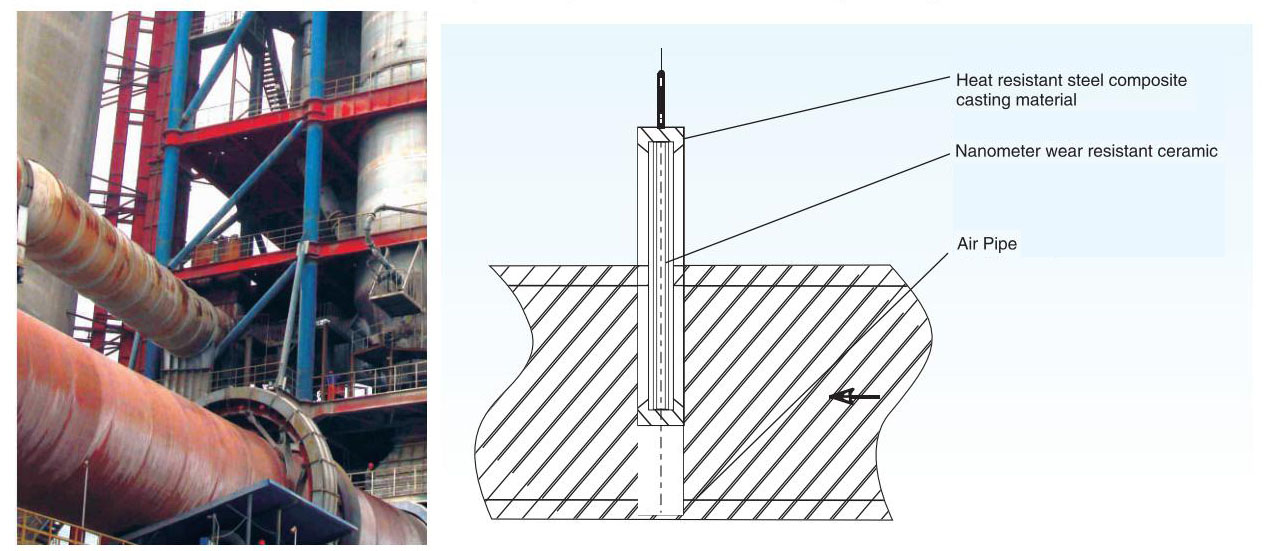

Tertiary air gate of nano-ceramic rotary kiln

Although the tertiary air gate plays an important role in the new dry cement production line, there are only two main materials currently used. The first one is pure heat-resistant steel plates (high-temperature stainless steel) with a service life of up to half a year. The second one is a heat-resistant steel-casting gate with a maximum service life of only about 8-10 months. Main challenges include that the gate is not resistant to high temperature or corrosion of complex gases (such as chlorine, alkali, sulfur, etc.); the gate is prone to serious deformation and jams; and casting materials may easily peel off and wear by particle erosion; and the gate is vulnerable to fracture and damage. To solve those challenges, our company has gathered the wisdom of experts, doctors, professors, and senior engineers and gone through years of evolution and numerous tests to successfully develop nano-ceramic tertiary air gates that can completely solve the challenges mentioned above. Adopts an all-ceramic structure, the gate has the characteristics of high temperature resistance, high strength, high hardness, high wear resistance, corrosion resistance, sound thermal shock resistance, and excellent oxidation resistance. The service life is more than 2-3 times that of heat-resistant steel castable gates. Featuring light weight and easy replacement, it can effectively reduce the maintenance frequency, improve the quality stability of cement, and save the production cost of cement. It can be applied in the new dry cement production line and existing cement production lines.

Product List

Luoyang Pengfei Wear-resistant Materials Co., Ltd.

TEL:

EMAIL:lypf0379@126.com

ADD:No. 1, Pengfei Road, Industrial Cluster Area, Ruyang County, Luoyang, China

© 2021 Luoyang Pengfei Wear-resistant Materials Co., Ltd. 豫ICP备16007321号-1 www.300.cn